Smart packaging solutions for a cleaner, healthier world

14.01.2025

There is an increasing demand worldwide for more and better packaging solutions. As well as improved performance, businesses and end consumers are prioritizing sustainability, driven by individual and corporate commitments and, increasingly, by legislation. Carpenter is at the forefront of these trends, offering customized packaging solutions that protect and cushion products while reducing the environmental impact of manufacturing and logistics.

Customization is key

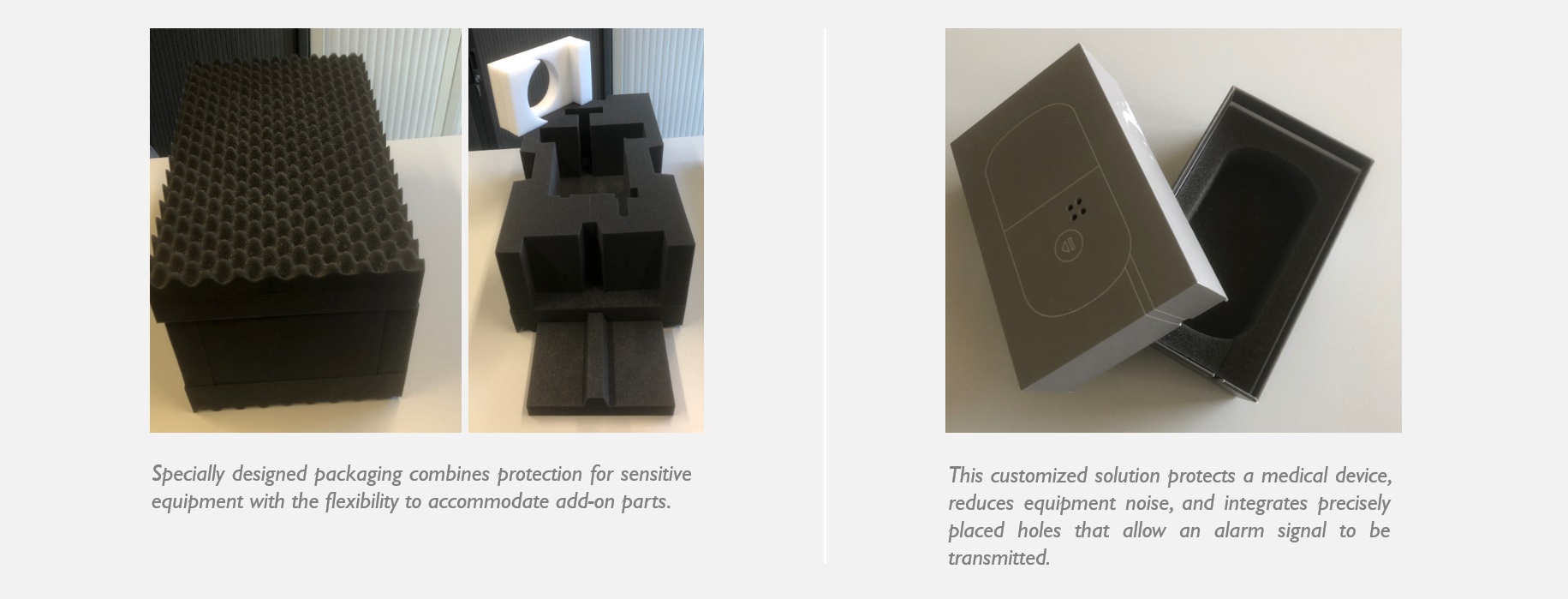

The cornerstone of Carpenter’s approach is a customer-centered approach resulting in products that are fine-tuned to performance requirements and designed as long-term solutions. From bespoke suitcases to custom-fit side padding and foam trays, the unique qualities of foam offer endless scope to create solutions that protect goods from damage, present them in an attractive way, and integrate product-specific requirements such as anti-static properties.

The design process starts from a thorough understanding of the individual project’s needs. We work closely with our customers, sharing information on the logistic strategy, product shape, specific performance requirements and cost targets. Next, based on either 3D drawings or an actual sample of the part to be protected, we create a design proposal for approval by the customer. Once the design has been approved, we create a prototype for testing. If requested, a trial order can be placed and delivered to test the packaging in the customer’s logistic flow. This collaborative approach means that the customer can provide input right up to the final delivery of the packaging solution.

Making a difference through eco-design

As demand for packaging increases, so does the need to reduce its environmental impact. Carpenter integrates eco-design principles at the development stage to reduce CO2 emissions and waste throughout the supply chain.

Our commitment begins with the creation of the foam itself. Our polyethylene and polyurethane foams are manufactured using recycled ingredients where possible. These include bio-polyols from different natural sources and recycled polyols derived from chemical recycling of end-of-life foam products. We also use mass balancing of raw materials, a ‘chain-of-custody’ approach which is helping to increase the proportion of certified sustainable content throughout the supply chain.

Our tailored approach leads to improved yield from foam materials and less waste from manufacturing. The solutions themselves are designed for durability and long-term reusability. They are lightweight, occupy minimal space in transport and create minimal emissions.

Our smart packaging solutions are customized and reusable, reducing the amount of material use and waste.

Read about our tailored solutions for sensitive medical samples